Screw size:6–200 mm in diameter

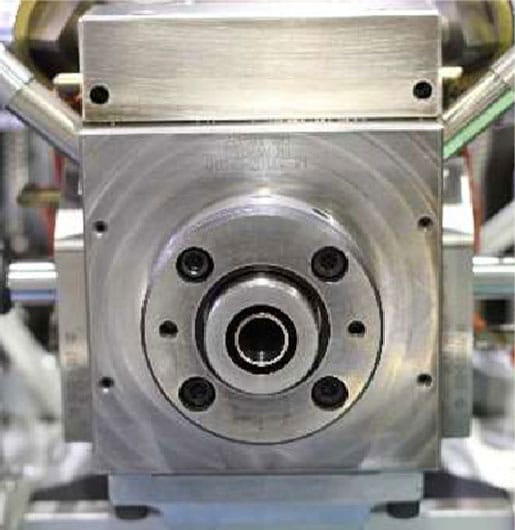

Melt pumps: 0.2–60 cc in output volume

Fluoropolymer-compatible corrosion-resistant products also available

Tube dies

Various types, such as single layer, multi-layer, multi-lumen

Coating dies

Sheet and film dies

Various types, such as multi-manifold and field block

Blow dies

Strand dies, monofilament dies

Dies with irregular shapes

Water cooling tanks

Various sizing units

Vacuum low-pressure sizing, high-pressure sizing, dry sizing

Internal pressure devices

Stretching devices

Vulcanizing devices

Take-up machines, pullers

Winding machines

Dancers (tension control devices), accumulators

In addition to the above, we develop a wide range of in-line

equipment, such as corrugators and

tube stretching devices, etc.,

in response to customer requests, all in-house.

Please feel free to contact us with the specification

of your product & process,

such as dimensions, materials and production speed;

we will offer the right equipment.

Contact